Home > Events >Cycle Development of VPHP Decontamination Cycle

Cycle Development of VPHP Decontamination Cycle

Cycle Development(CD) is to find an

optimized recipe for a dedicated area with certain condition temperature /

humidity/ VPHP design / loading pattern/vapor flow/ size of the chamber/the

machine in side / materials and so on.

The Key for CD is to find out the dead

leg or worst location of decontamination in such condition. This article shows the basic method of CD for

VPHP.

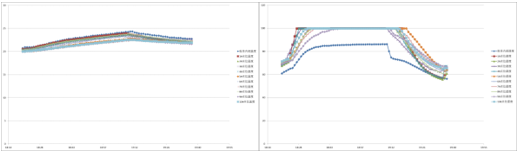

Based on Temperature & RH mapping,

Load pattern qualification, Airflow research, and the result of chemical

indicators test, we can find out the possible worst locations.

Temperature & RH mapping

And we will challenge the worst location for a well-qualified D value to tell the log reduction of certain parameters. (D value is the time that biological indicator population reduces 90% in certain sterilization condition.)

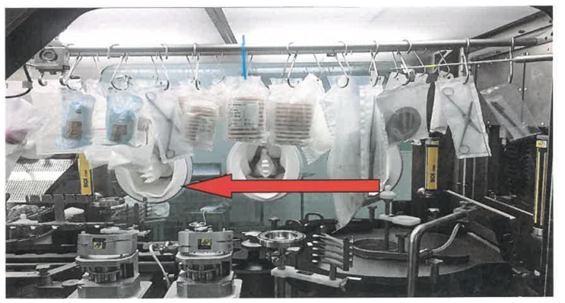

Load Pattern Qualification

LHSKP method for Test D value

After all

these, an acceptable safety margin will be set to your spore kill level,

sometimes even above 12 log reduction.

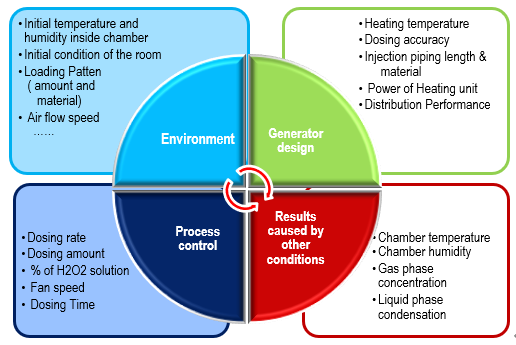

Factors

That Affect Decontamination

Key Factors can be category into: Environmental Factors, Generator Design Factors, and Cycle Formulations. Any of these changes will affect the parameters that shown on the report.

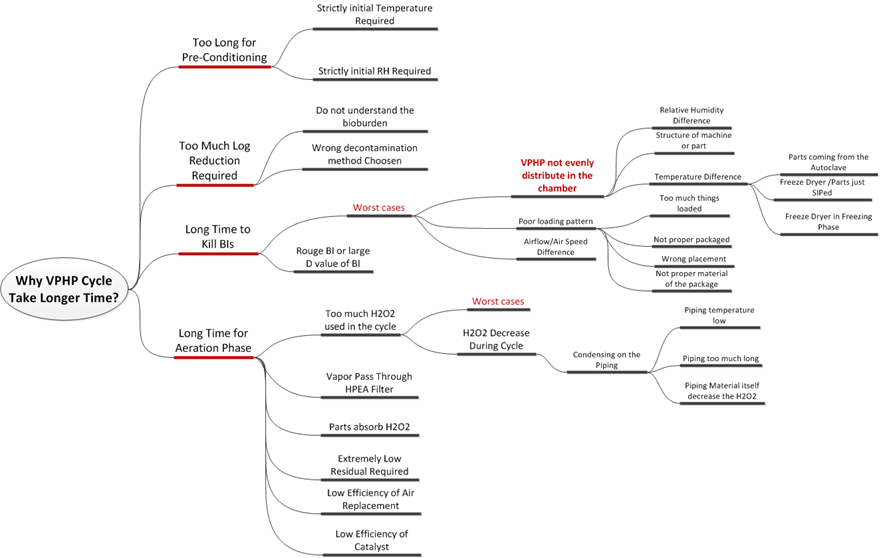

Shorten the Cycle Time

The Diagram listed below is the consideration of issues

cased long cycle time.

The main cause that affect the cycle time is the dead leg of the cycle or change another word the distribution of the VPHP inside the chamber. Dead legs directly increase in usage of quantity of H2O2 and cause longer time to aeration. Many new method of Vapor Phase H2O2 decontamination is developed to solve this problem, such as Ultra Decon®.

Long Cycle Time Cause Analysis

Enzyme Indicator (EI) - A New Technology

to Support CD

It takes time and cost hundreds of BI to do the D value test. And sometimes you will meet “rogue” BI which are hard to killed, that cause even more difficulty to your CD.

To fasten the CD, a new technology, so called Enzyme

Indicator (EI), is used.

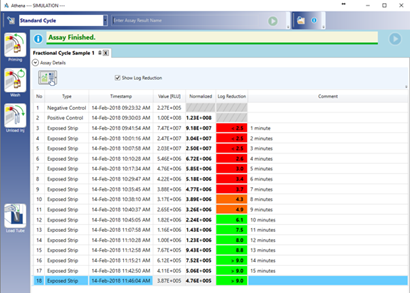

EI is a new and great tools help with the CD. EI itself is

a strip, which is pasted to the inner side of the surfaces of isolator, which

is no different from the use of CI and BI. The result of EI is analyzed by a

reader to measure the fluorescence reaction of the enzyme, telling you the

exactly log reduction of the kill level in certain correlation with BI. All the

data result is generated in the software.

EI can help to optimize the amount of the H2O2, and shorten the time of cycle. Tofflon introduce this technology in 2020 and enhance the ability of CD and have benefit to customer for their CD applications.

Conclusions

CD is an important activity for VPHP application, which give a scientific basis for cycle parameters and cycle validation.

EI can improve the cycle of VPHP and shorten the time of

CD.

Reproducibility is rely on factors inference studies and

all factors need to be controlled during every VPHP cycles used for dedicate

purposes.