Mini KUFill——Small Scale Filling Isolation System

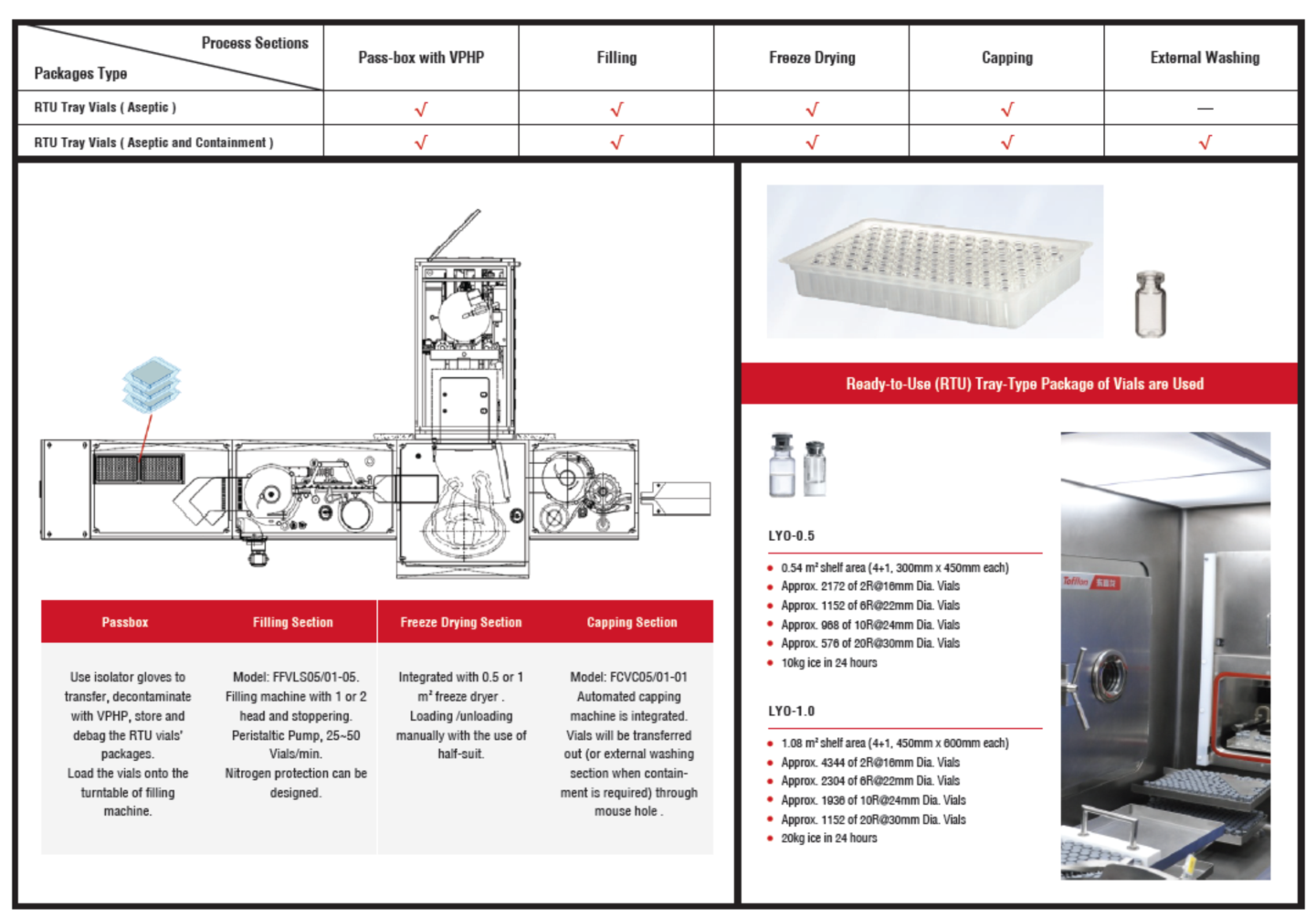

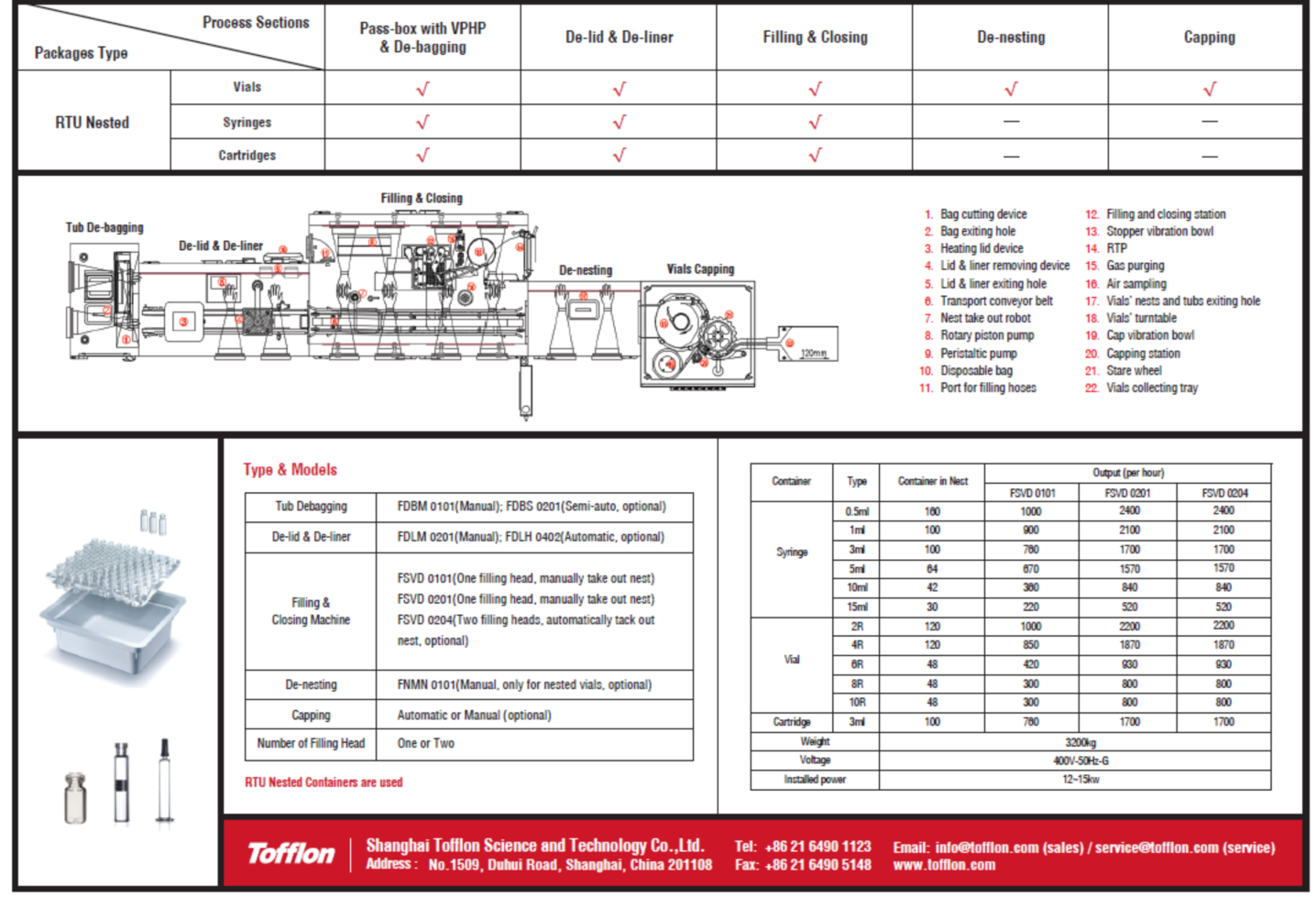

Mini KUFill, a system that includes aseptic processing line integrated with isolator, is specially designed for small scale production of injection for R&D or clinical trials purpose.

Mini KUFill offers you flexible process solutions at low risk of contamination; and it meets all cGMP and FDA guidelines for aseptic manufacturing.

Key Features & Advantages

- Single or multi-functional of filling and closing process can be integrated according to your products and at a dosing speed around 25~50 vials/min.

- Mini KUFill is expandable design to the possibility of integration with other process machines such as washing machine, dehydrogenation tunnel, freeze dryer and so on.

- Custom design is also available, which is suitable for different layout arrangements

- Ready-to-Use and Single-Use Technology benefit the promotion of a quick shifting between processes and reduce the risk of contamination.

Mini KUFill Isolator benefits

Multiple products adaptable.

Capable of aseptic and containment manufacturing application.

Compact design, accompanied in smaller area.

Lower classification of the room ( > EU Grade D or ISO 8 ).

Less gowning and less environment monitoring in clean room.

Quick changeover.

Less consumption of utilities.

Mini KUFill Isolator Highlights

Aseptic & Containment Design

- Isolator chambers are designed for easy cleaning, washing and draining.

- WIP/CIP function is equipped for containment isolator.

- Bag-in-bag-out HEPA Filters are used in air return ducts of isolator.

- Connections are reserved for WFI or other process utilities.

Integrated VPHP System

- Stable parameters control ensures a reproducible validated cycle to achieve 6-log spore reduction against highly resistant BI.

- A high efficiency catalysts unit is used to break the high concentration H2O2 vapor rapidly during aeration.

- 1 ppm or even lower concentration can be achieved (30 ppb) at the end of aeration phase.

Integrated Control System

- All of machines share one control system.

- The user will get benefit from easy of operation on one HMI and get the key process data on one report.

- The software is designed to meet 21CFR Part 11 and GAMP 5.

- The total production will be highly integrated, safely interlocked and reliably recorded.

Environment Control

- Isolator offers a Grade A (or ISO 5) unidirectional airflow in the critical process area.

- Particle counters and microbe samplers are equipped.

- An AHU (Air Handling Unit) also can be equipped to control the temperature and humidity inside the isolator if the process requires.

- Concentration of H2O2 will be monitored not only in the decontamination cycle but also in production.